When the sudden onset of the pandemic forced food retailers to confront a deluge of demand for online grocery services, mechanized systems that could supercharge stores’ ability to pick and fill orders seemed like an obvious solution.

More than two years later, however, automated micro-fulfillment centers (MFCs) remain a rarity in the grocery space, with retailers still heavily reliant on human workers to manually gather products for digital customers. Meanwhile, retailers have adopted systems that help those employees assemble orders more efficiently, posing a challenge to MFC vendors as they look to demonstrate why their equipment is worth the substantial amounts of money needed to install and maintain it, according to retail and supply chain industry experts.

In addition, retailers have recently been focusing on core issues like managing inflation and keeping their shelves stocked in the face of supply chain constraints, taking their attention away from technologies that might not be central to those efforts. At the same time, while online grocery sales remain elevated compared with pre-pandemic levels, shopper interest in e-commerce is not increasing at the explosive rate it was earlier in the public health crisis.

“They’ve invested in their in-store operations and their in-store picking … and so what they’ve done is raise the threshold or barrier that the micro-fulfillment center needs to jump to demonstrate its ROI,” said Barry Clogan, chief product officer of Wynshop, which provides e-commerce platforms to retailers.

A largely untapped market for micro-fulfillment technology

In an illustration of how slowly MFC technology is showing up in the grocery industry, Takeoff Technologies, which is working on MFC projects with retailers including Albertsons and Wakefern Food, has so far installed just 22 systems, said Mitchell Freeman, the company’s chief financial officer and chief strategy officer. Takeoff has about 100 more MFCs in the development pipeline, even though the company believes there is a potential global market for at least 15,000 MFCs, Freeman added.

“We know that we’re only in the early innings of this industry,” Freeman said. “There's a lot of hard work and a lot of energy that still needs to be spent on building the right portfolio solutions.”

Freeman said MFCs have the potential to help grocers reduce costs for shoppers without losing money on e-commerce.

“The desire to buy online has not changed. What has changed over the last six months is [shoppers’] demand for a much more competitive price when they do buy online, and we're seeing commentary in our commercial conversations that suggests that the grocers are seeing this, and that they need micro-fulfillment now more than ever,” Freeman said.

A key factor for MFC vendors is that food retailers have historically been slow to integrate technology into their operations — a dynamic that remains in place today even though e-commerce represents a much larger share of the grocery market than it did before the pandemic, said Tom Furphy, a former Amazon Fresh and Wegmans executive who is now CEO and managing director of Seattle-based venture capital firm Consumer Equity Partners. Furphy is also CEO of Replenium, a supplier of automated replenishment technology.

“I think the ROI is still there if the volumes are there,” Furphy said. “I just think we haven’t had the urgency in the immediate term.”

Even as the grocery industry has found ways to manage e-commerce demand manually, retailers have yet to find ways to turn their online grocery operations into consistently profitable ventures, Furphy pointed out. That could drive demand for MFCs down the road, particularly if retailers continue to find it hard to turn a profit on e-commerce despite launching innovations like membership programs to pass on some of their fulfillment costs to grocery shoppers, he said.

‘The payback is not obvious’

A central question retailers need to address is how long it will take them to make back the cost of putting in an MFC — a figure that is directly related to the number of orders they process in a given period of time, said Marc Wulfraat, founder and president of MWPVL International, a supply chain consultancy based in Montreal.

A typical MFC can pick between 350 and 500 items per hour and takes from 7 to 10 seconds to gather each product, according to figures from MWPVL. By contrast, human workers in a store generally take about 75 seconds to pick a single item, Wulfraat said, noting that multiple items of the same kind, such as two cartons of eggs, are counted as one unit.

“If you're the owner of a grocery business, and you're considering automation in the micro-fulfillment context, the payback is not obvious. It's not as though it says, ‘Hey, in a year and a half, you’ll be done and the cash is going to start flowing in.’”

Marc Wulfraat

Founder and President, MWPVL International

MFCs start providing a financial return after handling about one million orders, but getting to that point can take years, given that grocers venturing into automation typically start at about 5,000 orders per week, or 250,000 per year, Wulfraat said. By comparison, the sprawling robotic fulfillment centers Kroger is rolling out across the United States in partnership with U.K.-based automation company Ocado can handle 250,000 orders in a single week, according to MWPVL.

“If you're the owner of a grocery business and you're considering automation in the micro-fulfillment context, the payback is not obvious,” Wulfraat said. “It’s not as though it says, ‘Hey, in a year and a half, you'll be done and the cash is going to start flowing in.’”

Wulfraat said retailers he works with are taking a cautious approach to determine whether investing in micro-fulfillment technology is worthwhile, in part because they are waiting to see how the various solutions on the market develop. “They’re very interested in the technology [but] they want to understand who’s making what moves, what vendor solutions seem to be pulling together in the horse race. So they’re not quite ready to push the button and take a chance,” he said.

Rising labor costs and hiring challenges stemming from the tight job market, however, are shining a spotlight on technology that can accomplish tasks without human involvement, potentially changing the calculus for retailers unsure about whether to invest in MFCs, according to Wulfraat.

In addition, the number of working-age people will decline as the population ages during the coming years, Wulfraat added. In a reflection of the connection between automation and demographics, the companies that build the systems at the heart of MFCs are centered in Europe and Asia, where the average person is older than in the U.S., Wulfraat said.

“Finding someone to go and pick ... orders in your store isn't as easy as it used to be,” said Wulfraat. “There has to be a way to do it better, because this isn't going away.”

Looking for a balance of cost and utility

Factors like geography, customer preferences and promised fulfillment speeds all play a role in determining how and if automation could benefit a retailer’s e-commerce operations, Wulfraat said. In a reflection of this, he noted that even as Kroger focuses on large-scale facilities as the foundation of its automated fulfillment network, the grocer is using micro-fulfillment technology to serve the Miami area.

Wulfraat said he thinks mid-size automated e-commerce fulfillment systems designed to serve an entire metropolitan area, like the facility The Giant Company debuted last year in Philadelphia using technology from AutoStore, could turn out to be a “sweet spot” by offering retailers an optimal balance of cost and utility.

“Not only is this a way to handle online orders for existing customers, it's a way to grow sales,” Wulfraat said. “So to my mind this is the poster child of what MFC will likely become.”

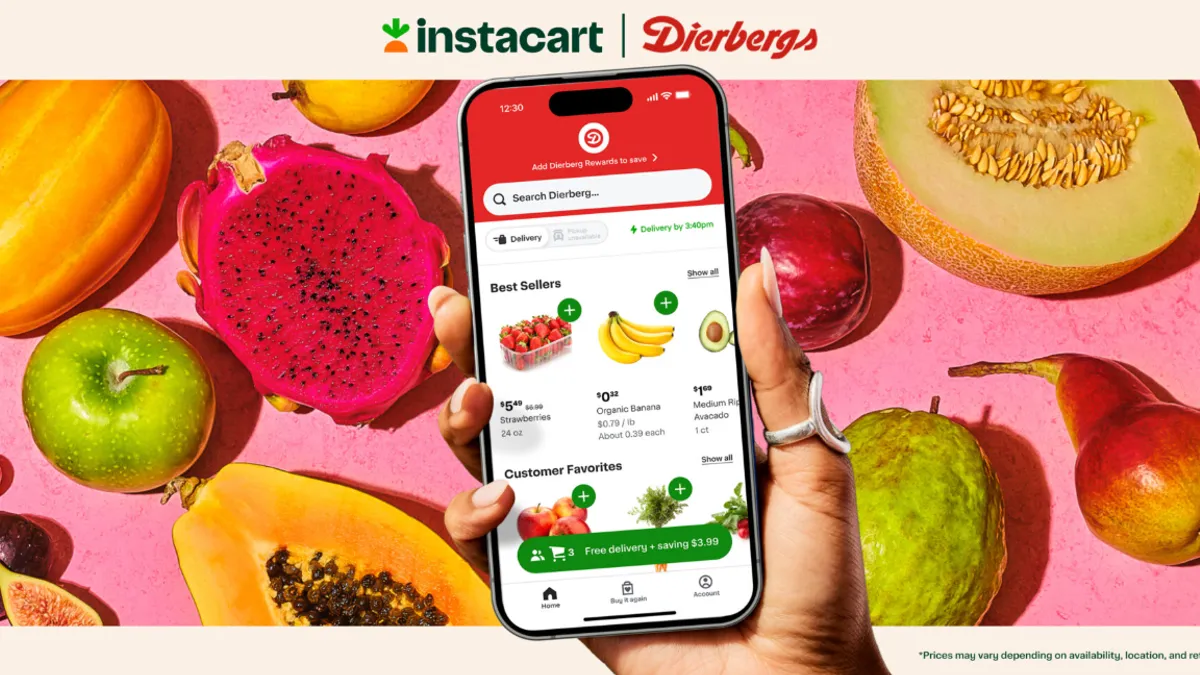

Instacart has partnered with MFC vendor Fabric to offer a solution for grocers that see a need for MFC technology but don’t want to invest the resources or time to develop automated fulfillment facilities on their own. But the companies have yet to announce a customer for their service more than a year after agreeing to work together.

In an emailed statement in response to questions about the Fabric tie-up, an Instacart spokesperson said the company works “to help retailers devise and implement new fulfillment models” through Carrot Warehouses, a suite of services for grocers it rolled out earlier this year, but did not provide details about the partnership.

“As part of Carrot Warehouses, we work with retailers to build a model that’s tailored to their specific needs. Some will choose to leverage automation – and Fabric is one example of a technology provider that they can leverage,” the spokesperson said.

The spokesperson added that Instacart offers “faster, more accurate delivery” using what the company refers to as “nano-fulfillment” centers, but did not identify the source of the technology Instacart uses to provide that service.

Wulfraat said he thinks Instacart is likely to see interest in automated fulfillment services from retailers in large markets where order volume puts pressure on its in-store picking model.

“If it’s not a problem, why would I want to pay that extra fee for the automation? [But] if I've got 40 to 50 people in my store at the same time picking online orders and my extra customer sales are dropping because of it, I'm not going to be too happy” and might be inclined to look at automation, said Wulfraat.