The grocery industry is more competitive and complex than ever before. Trends such as sustainability, omnichannel shopping and digital transformation were once barely a blip on the radar. Now, they’re driving the industry toward its future, and grocers must respond.

That brings us to a potential opportunity in what might be a surprising place: the label materials used in weigh-scale and other variable information (VI) print applications. Switching to linerless labels could have a lasting, positive effect on efficiency, sustainability and overall business success. They could play a small but crucial role in helping grocers future-proof their business.

What is a linerless label?

In lieu of having a film or paper liner, linerless constructions employ a facestock coating that allows each layer of labels to peel cleanly and easily from the layer beneath it. First introduced more than a decade ago, the technology has been refined over the years. Today’s linerless labels are more reliable and easier than ever to use

Another key benefit is that linerless labels use approximately one-third less material than traditional labels. And the entire roll is put to use: There’s absolutely no liner waste to step around (and hopefully not slip on), sweep up and dispose of.

Linerless and sustainability

The grocery industry has been under tremendous pressure in recent years to operate more sustainably. As significant as this pressure has been, it stands to increase in coming years as new regulations and consumer expectations force major brands to account for and manage their Scope 3 carbon emissions.

Scope 3 refers to carbon emissions across a company’s value chain. So, companies that make many leading consumer brands will need unprecedented levels of data transparency and carbon emissions management from the grocers that carry their products. The bottom line? Many grocers will likely need to scrutinize their operations, looking for even more ways to lower their carbon footprint.

Enter linerless labels, with less material going in and less waste coming out. And because a roll of linerless labels weighs less, they ship more efficiently and help contribute to an upstream reduction in carbon emissions.

Linerless and omnichannel shoppers

Shoppers who choose to engage with a retailer through multiple channels are very attractive. According to a 2023 study by Grocery Doppio, omnichannel shoppers spend nearly one and a half times the amount of money per month as single-channel shoppers.

What’s the hitch? It’s challenging for grocers to execute an omnichannel business model profitably. As noted in a recent article by McKinsey and Company:

“As grocers think about profitable operations for online grocery with these raised stakes, they shouldn’t look for a silver bullet. Instead, an interconnected series of decisions across the value proposition and their impact on operations—including network design, order preparation, last mile and best-in-class processes—will be crucial to bend the curve toward profitability. With many decision points across the omnichannel journey, a coordinated and consistent strategy will be critical for success.”

With that in mind, adopting linerless label technology could help grocers improve workflows while reducing waste. Because they can fit more labels per roll, linerless labels require less changeover, helping employees stay focused on more profitable activities. Less waste means less cleanup, again saving employees time and effort.

Linerless and the shift to newer technologies

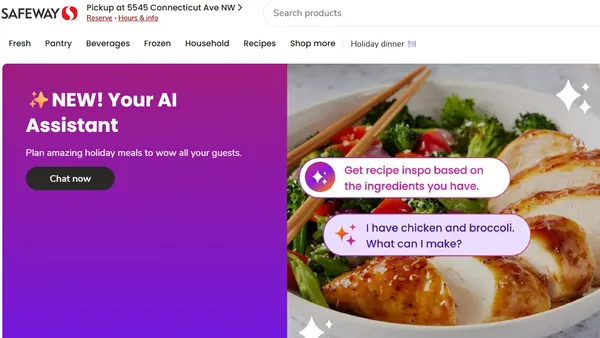

Technology is transforming many retail industries, including grocery. New tools, including AI, have incredible potential to help companies be even more flexible and responsive to shopper needs. As McKinsey notes in another recent article, “Agile, digitally savvy retailers that can derive the most benefit from new technologies will speed ahead of competitors and increase the value they provide to shareholders.”

Linerless labels are a highly flexible and adaptable print platform that can benefit many store operations. As grocers consider new technologies that can help them gain an edge over the competition, they should consider linerless.

It may be time to look into linerless

Intrigued by how linerless labels can help you future-proof your business? The place to start is with your label printer hardware provider. They can help you run the numbers and understand your potential ROI of switching to a linerless platform. And know that companies such as Avery Dennison offer the linerless label materials you’ll need to make the most of this technology.