As an engineer, I've spent years—more like decades—perfecting retail technologies in labs well before they made an in-store appearance. Each development phase included painstaking rounds of testing and validation to ensure products worked according to exact specifications. While this mindset and methodology work for many facets of retail automation, it's not the way to roll out in-store robots.

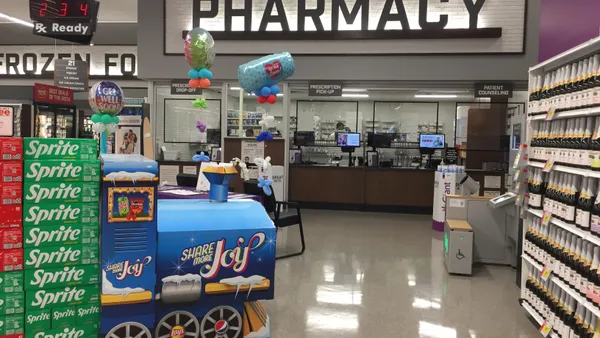

In the grocery world, each store is defined not just by product quality, but also by its unique culture, clientele and employees. There's no one-size-fits-all solution, especially when bringing a robot into the operational mix, a key point we've learned from deploying more than 500 grocery robots since January 2019.

Our robots were initially trained in a simulated grocery environment to spot hazards that could cause slip-and-fall accidents. We spent months teaching them how to recognize everything from runaway grapes to spilled milk. Along the way, the robots were introduced to various floor surfaces and the differences between puddles of water and oil. This was accomplished while putting pallets, boxes and all types of obstacles in their paths.

Into the Wild

Then we did something counterintuitive to the thinking of most engineers: We put the robots "into the wild" with a series of pilots in real-life stores. No disrespect to the lab testing, but the fastest results came when robots roamed the aisles safely alongside customers.

Once we got past shoppers' gasps of "what the heck?" and sighs of "why is this thing here?" from employees, robot training went into hyper-drive. There was daily input on sounds, speeds, lights and action. Meanwhile, robots took over hourly floor inspections. While this chore traditionally took up to 45 minutes of monotonous, manual effort, robots completed the task quickly and efficiently—without smoke breaks.

As the robots made their daily rounds, shoppers (especially pint-sized ones) were eager to see, touch and interact with them. Early customer engagement was priceless in refining behaviors, ensuring robots didn't follow customers too closely or wait too long for someone to move.

No amount of lab testing would have yielded such invaluable insights into a day in the life of a grocery robot.

Fast Time to Value

Testing in stores also produced pleasant surprises. We expected testing to last from three to nine months. In reality, early adopters reported overwhelmingly positive feedback within weeks.

What's more, retailers were shocked by the groundswell of community support. Kids of all ages flocked to the stores to take selfies with the robots. As public awareness and acceptance grew, so did stores' adoption rates.

Once the benefits of automating floor inspection became clear, retailers wanted more. They turned to monitoring shelf conditions to detect missing, mispriced or misplaced inventory. Forward-thinking grocers already are adding temperature checks, along with lighting and security details, to the robots' expanding list of tasks.

Outside merchants and suppliers also have joined the robot fan club. They are collaborating to determine how these mobile data collection systems can help improve merchandising performance and planogram compliance.

In-Store Robots are Here

The question of whether in-store robots bring retailers value has been answered with a resounding "Yes!" Now, the burning question is how can you best operationalize all the robot-collected data and analytics to transform operations?

To date, the Badger™ robots have traveled more than 250,000 miles of store aisles across nine states. They recently rolled across the pond into stores and pilots in Australia, New Zealand, Germany and the Netherlands. Thanks to agile development, on-the-fly changes and modifications, retailers gain the flexibility to customize speeds, sounds and lights in keeping with geographical, cultural and organizational preferences.

It's just as easy for robots to sport a British accent as it is for them to pass customers on the left in a UK store. Basic functionality is the same, it's just a matter of personalizing behavior so the robots fit in the flow of store traffic and use proper manners with human co-workers and customers.

The best way to evaluate in-store robots is by testing in real stores. The sooner you bring them in, the faster you can determine how they'll help you stay relevant and competitive. So, tire kickers beware—find out what innovative retailers already know: In-store robots are worthy comrades when it comes to combating continued disruption across the brick-and-mortar landscape. The time is now, so don't delay.

Tm Rowland is CEO of Badger Technologies™, a product division of Jabil.